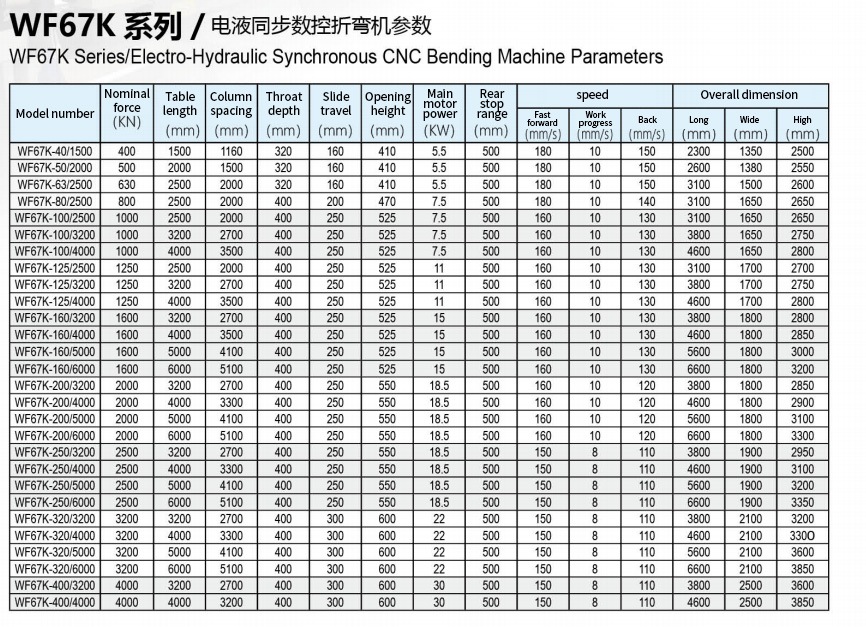

Electro-Hydraulic CNC PressbrakeBending Machine

WF67K series hybrid CNC pressbrake (mechanical compensation) is a multi-purpose energy-saving and high-precision pressbrake tailored for customers' specific applications. Numerous machine options and automation options make every press a complete custom solution. The WF67K models are available in single unit configurations ranging from 30 tons to 3,000 tons meters.

1. Using high-performance servo motor, saving more than 30% of energy. Supply oil on demand, reduce overflow, effectively reduce oil temperature, and extend the service life of hydraulic system and components.

2. High-performance electro-hydraulic servo system, full closed-loop control slider synchronization, repeatability 0.01mm.

3. Standard DELEM numerical control system, ESA, CYBELEC and other series numerical control system can be selected.

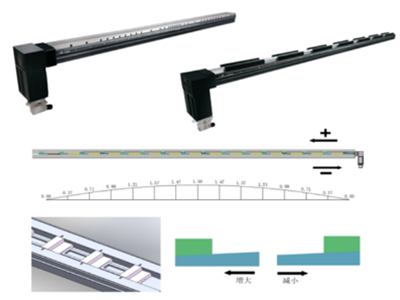

4. The table adopts CNC system to control the mechanical deflection compensation device.

5. Backgauge is equipped with high-performance servo motor and ball screw.

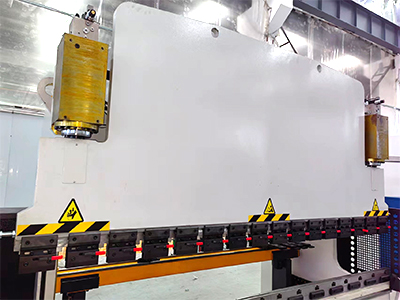

6. Standard fast tool change and clamping device, quick clamp with wedge type. Angle compensation function, safety hook to prevent top tool falling off.

7. Single V, double V or multi-V die can be selected.

8. Optional linear guide front supporting rack.

9. Optional installation of safety grating to prevent machine pressure safety accidents.

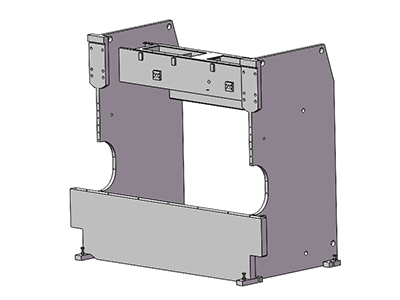

| Machine tool structure |

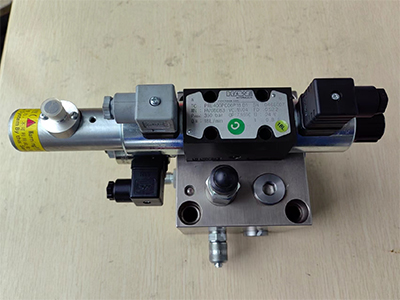

Y1 ~ Y2 axis Y1 ~ Y2 axes are two independent moving axes of cylinders controlled by CNC system. Two linear scales Y1 ~ Y2 are installed at both ends of the machine, which are used to determine the exact distance between the slider and the table. The linear scale is connected with the table to eliminate the influence of the column deformation on the position of the slider. When the slider is running, the position data is immediately fed back to the numerical control system, which can calculate and output the servo valve control signal S1 ~ S2, control the output flow of the two electro-hydraulic servo valves, and synchronize the two cylinders. |

|

| Anti-Deflection Table The V-axis is a CNC axis that controls the amount of convexity added to the table, allowing accurate deflection compensation over the full length of the table. The crowning table is composed of a number of integral convex wedge iron with beveled surface, which can move relative to each other to form a group of positions. The deflection compensation of the table is automatically carried out by the computer, and the accuracy of the machine is retained after several years of use. The deflection curve fits the deformation curve in the full length range so that the full length Angle is consistent. The automatic correction and compensation capability provided by the system is convenient and reliable. |

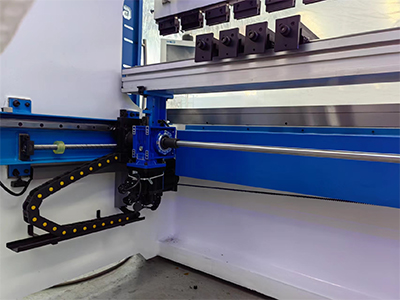

Backgauge |

|

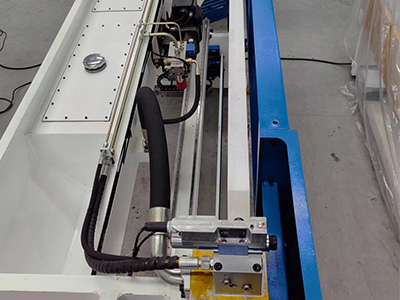

| Hydraulic system 1. The whole system is equipped with main servo motor, saving energy and reducing noise |

Slide front support |

|

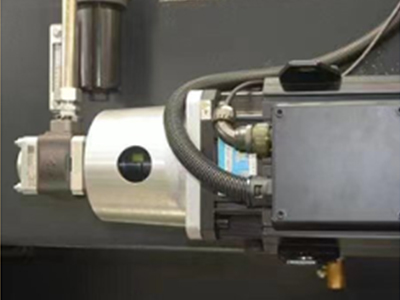

Main motor |

European-style fast clamp |

Servo motor |

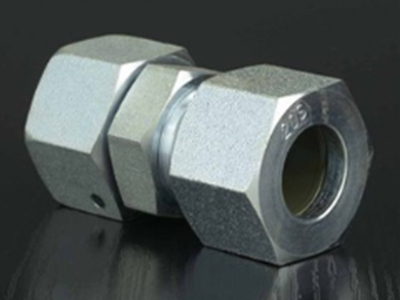

Bushing joint |

Hydraulic valve |

Proportional valve |

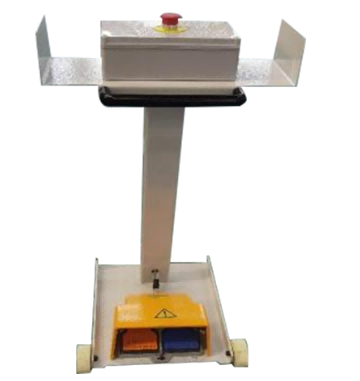

KACON foot switch | |

Optional 6-axis CNC backgauge

Optional 6-axis CNC backgauge