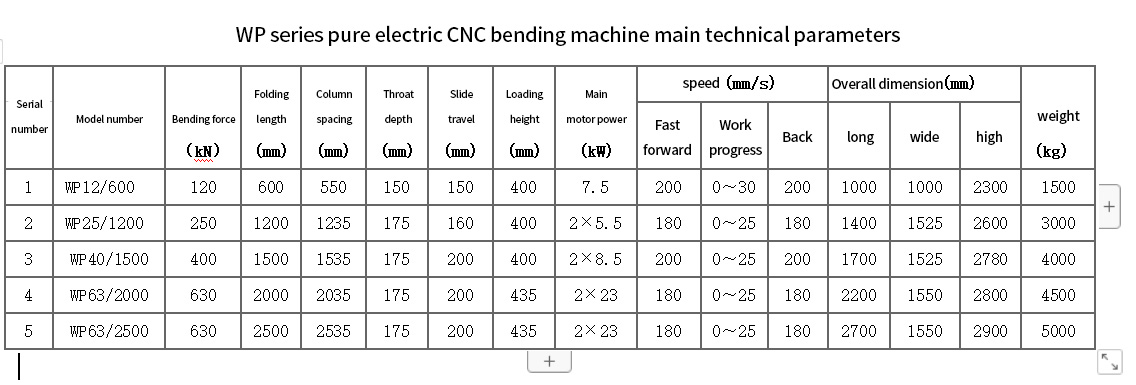

Electric Servor PressbrakeBending Machine

1. It has the characteristics of safety, high efficiency, energy saving and green environmental protection, as wellas accuracy and convenience.

2. CNC system of pure electric servo bending machine, the synchronization accuracy of the slider is high and accuracy is ±0.01.

3. Servo + right angle reducer drive slider, heavy precision screw, fast speed, low noise, high control accuracy.

4. Imported high precision linear magnetic grid scale feedback full closed-loop control mode, accurate positioning control, repeated positioning accuracy reaches ±0.005.

5. Bending pressure automatic calculation function, exceeding the pressure limit range alarm.

6. Angle intelligent compensation function, according to material characteristics, size of die, material thickness, bending angle and other sheet metal process parameters, combined with the numerical control system Angle calculation model, any sheet metal only needs a test bending can be automatically corrected according to the angle deviation.

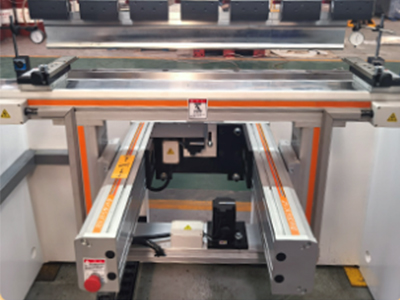

7. Backgauge is driven by AC servo motor, and the transmission system adopts no-gap ball screw and linear guide rail to ensure accurate and reliable positioning. The "direct" calculation function of the rear material position: according to the relevant size and plastic deformation of sheet metal, the position of the rear material is directly calculated according to the neutral layer.

8. Electrical components and materials are imported brand-name products, in line with international standards, safe and reliable, long life, strong anti-interference ability, electric control cabinet has heat dissipation function.

9. Five-wire touch screen, high reliability more than 10 million times of service life, simple and fast operation process.

10. The upper slider is equipped with a wedge type deflection compensation mechanism.

11. Arc continuous bending function.

12. Tooling parameter library: Establish tool parameter library for customers to facilitate customers to quickly invoke parameters for sheet metal bending.

13. Password protection.

| EP700B CNC system adopts high-grade industrial design of luxury panel, 15-inch large screen LCD display and touch screen, the interface display is clear at a glance.2D graphics programming function: the system has 2D graphics programming/display/simulation function, the operation image is intuitive, and the bending collision can be warned in the simulation bending. Direct programming function: the system has direct programming function at the same time, for simple bending using direct programming function is the most convenient, just simply input the back-end of each process, Angle and other parameters can be bent processing. High speed and high precision control The CNC system of the all-electric servo bending machine adopts high-speed acceleration and deceleration calculation method and trajectory foresight algorithm, etc., the CNC system in advance according to the bending speed and vector characteristics, the overall planning of the motion trajectory, at the same time of high-speed acceleration and deceleration, to ensure good bending accuracy and soft motion characteristics, so that high speed and high precision are effectively integrated! ① High speed: Y-axis maximum fast-forward speed 200mm/s, maximum feed speed 50mm/s. 2 High precision: using 5um resolution magnetic grid ruler and high-digit encoder double ring control, repeated positioning accuracy of ±3um. ③ Processing consistency: to avoid the impact of oil temperature changes on the consistency of the bending workpiece. |

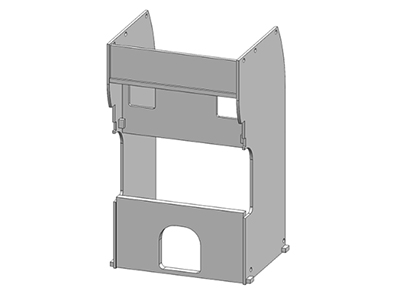

1. Latest technology design, complete steel plate welding structure, high strength, high stiffness; 2. The frame adopts German technology and uses annealing furnace as a whole to eliminate internal stress, with good precision;3. The main component structure is analyzed and optimized by using American ANSYS/UGS/CAD/CAM/IMAN 3D software. The structural parts are cleaned by sand blasting and sprayed with anti-rust paint. 4. The column, upper working slider and lower table of the machine tool are processed by the Czech Skoda or Qiqihar II-machine 5-axis boring and milling machine in one time to ensure the parallelism, perpendicularity and parallelism of each mounting surface. |  |

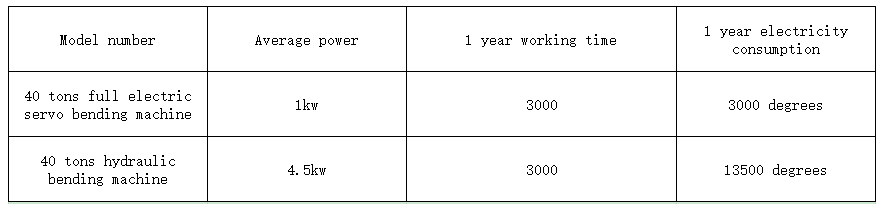

| Energy saving and environmental protection Full electric servo CNC bending machine, especially energy-saving and green environmental protection. Special power saving: The power difference between the all-electric servo bending machine and the electro-hydraulic servo bending machine is like the difference between the frequency conversion air conditioner and the ordinary air conditioner. The all-electric servo bending machine automatically outputs the appropriate power according to the working condition, and the power consumption is less than 0.5kW during idle time, so it is especially power-saving. Green environmental protection: no need to use and replace hydraulic oil, ending the waste hydraulic oil pollution to the environment. Power consumption comparison between 40 tons full electric servo bending machine and 40 tons hydraulic bending machine: A year can save electricity: 13500-3000=10500 degrees; Five years can save electricity: 52,500 degrees!

|

Intelligent safety light screen monitoring (optional) The electric servo bending machine CNC system based on safety light curtain signal and the parameters of the workpiece processing (CNC system set up and down mould parameters and workpiece thickness, etc.) and linear displacement sensor position feedback value, intelligent decision in the process of bending danger area and safe area, to protect the safety of operating personnel. This design solves the defects of the safety light curtain used in the existing market, which can protect the safety of the operator without affecting the work efficiency during the bending process. |

|

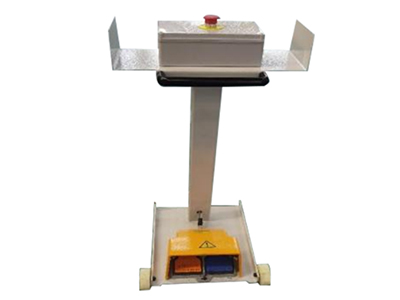

| Safety foot switch Safety foot switch is a high-performance product designed with safety and convenience as the focus, the system is equipped with Korean KACON foot emergency stop switch. |

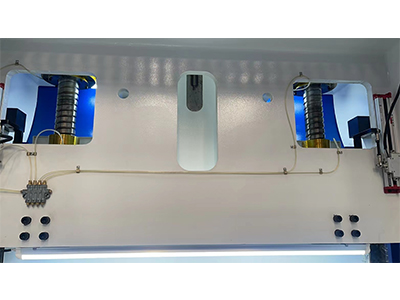

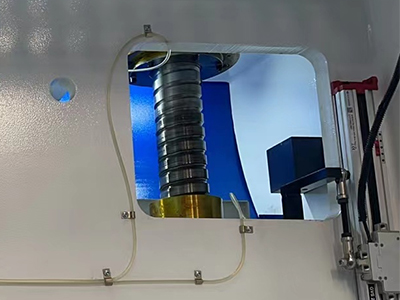

Spindle precision power box The main shaft power box can transmit bending pressure, with heavy duty ball screws and bearings, ultra-long life design, sealed protection design to ensure that critical components are not affected by external dust. |

|

| Servo main motor |

Rear feed servo motor |  |

| Reduction gear |

| CNC Backgauge - Full aluminum alloy 4-axis, to ensure the accuracy of bending process. The system controls the Z-axis finger to move left and right to ensure personnel safety. Imported ball screw and linear guide ensure the speed and accuracy of the backgauge. |

|

| Heavy lead screw |