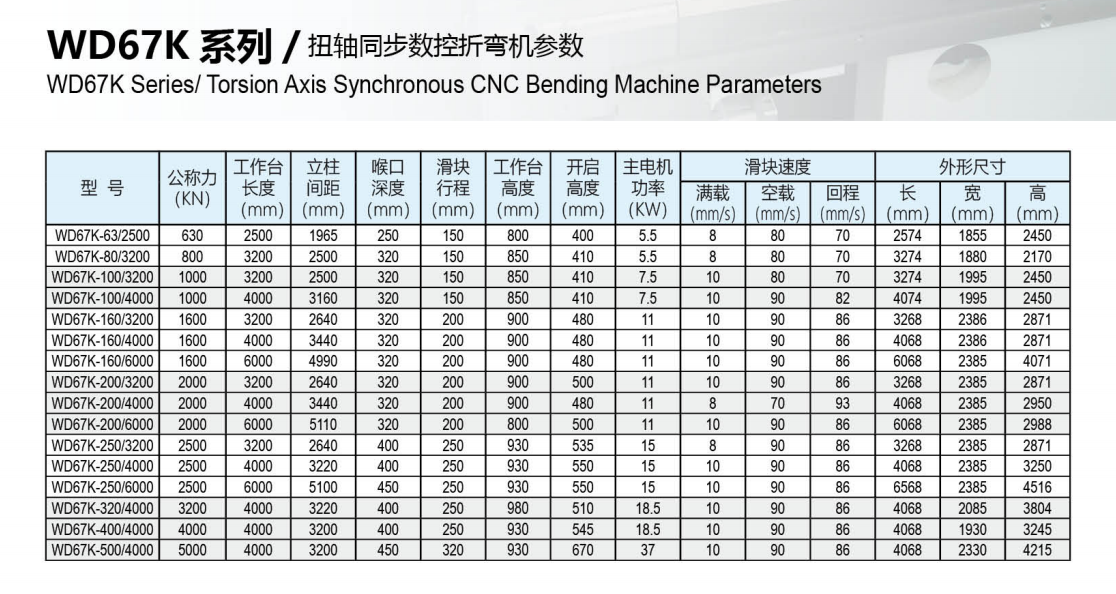

Hydraulic PressbrakeBending Machine

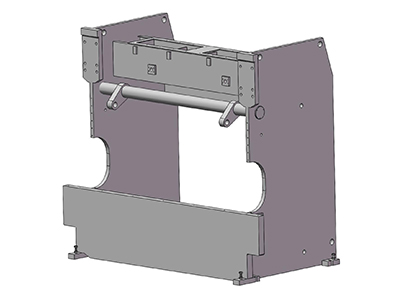

▪ Integral welded structure, and eliminates internal stress with sufficient strength and stiffness.

▪ Hydraulic upper transmission, sliding block adopts torsion bar structure, stable and reliable performance.

▪ Mechanical block structure, stable and reliable positioning accuracy, mechanical block is adjusted by the motor, counter displays the adjustment value.

▪ The bearing and slide guide surface of the torsional bar are made of advanced composite materials, which are wear-resistant and have low friction coefficient.

▪ Adjut mode including point, single and continuous stroke operation, easy to adjust.

▪ The electrical cabinet is equipped with a mechanical and electrical interlocking device, which automatically cuts off the power supply when opening the door to protect personal safety.

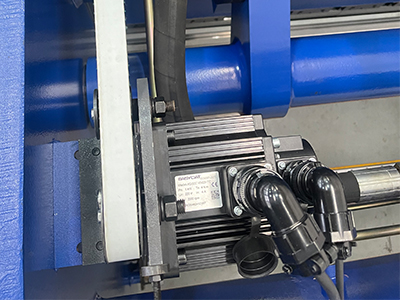

▪ The backgauge adopts servo motor, ball screw, linear guide rail transmission, high accuracy and stability, and the pressbrake bending system is adopted

SL Xinli self-developed CNC system to achieve multi-step bending programming and synchronization accuracy of the backgauge material.

| 1. New technology design, the whole steel plate welding structure, high strength, high stiffness; 2. The frame adopts German technology and uses annealing furnace as a whole to eliminate internal stress, with good precision; 3. The main component structure is analyzed and optimized by using American ANSYS/UGS/CAD/CAM/IMAN 3D software. The structural parts are cleaned by sand blasting and sprayed with anti-rust paint. 4. The column, upper work slider and lower table of the machine are processed by Czech Skoda or Qiqihar II-Machine 5-axis boring and milling machine in one time. Ensure the parallel and vertical degree and parallel degree of each mounting surface. |

1. Servo valve group driven by German BOSCH system. 2. The internal meshing gear high pressure pump by Japanese Hydraulic Co., Ltd. can stand high pressure and low noise. 3. The cylinder and piston rod are made of 45 steel hot forging. 4. The cylinder and piston rod are formed by Japan Toshiba 5-axis boring and milling machine and Japan Daiichi M132/300 CNC lathe. Cylinder grinding, hard chrome plated piston rod. 5. The hydraulic system has overload overflow safety protection,and the oil level height is clearly and intuitively displayed. 6. High-precision guidance system, position measurement system and hydraulic equalization function to meet the needs of full-length machining. 7. The machine can work continuously under the rated load, the hydraulic system has no leakage and continues to be stable, with high precision. |

|

KACON foot switch |

Slide front support |

European-style fast clamp |

Torsional shaft drive |

Servo motor of the cylinder around Y1 Y2 to be consistent |

Hydraulic valve group |