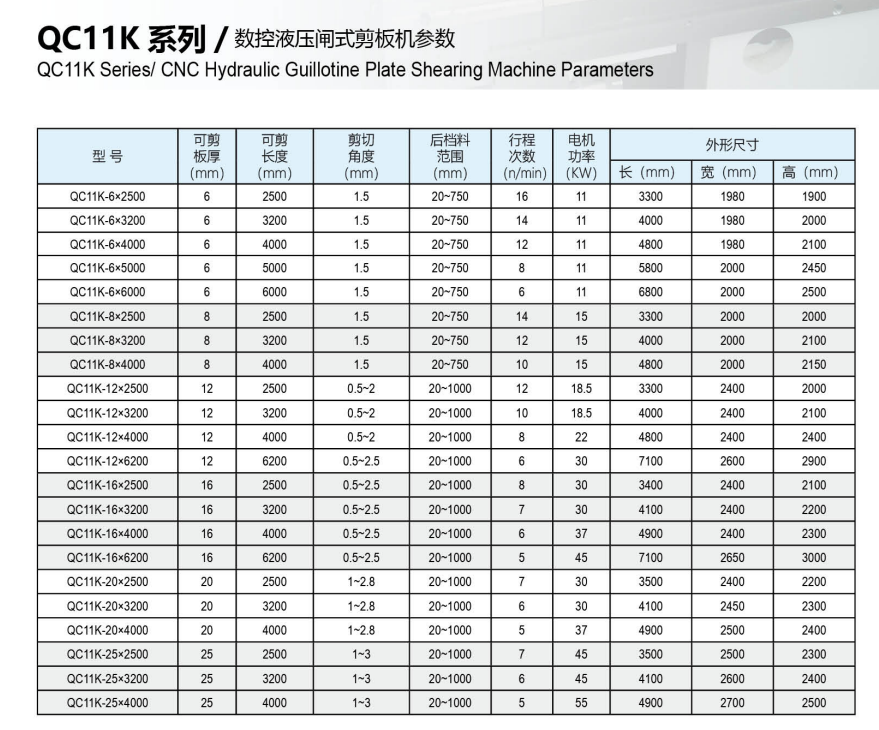

Hydraulic Guilllotine ShearsShearing Machine

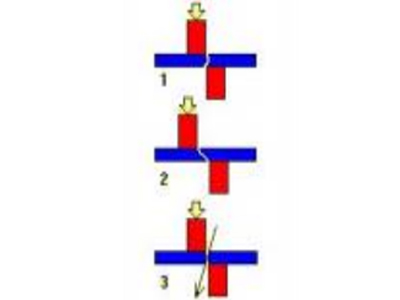

1. Guillotine shear, reduce sheet material distortion.

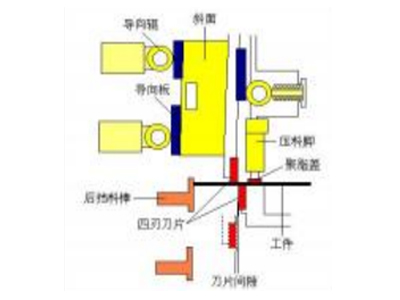

2. Three-point roller guide structure, the front prepressing guide rail makes the tool holder always stick to the upper guide rail and the lower guide rail for reciprocating movement without gap.

3. Blade clearance adjustment mechanism, to meet the cutting needs of different plate thickness and material.

4. One set of standard rectangular blade can be cut with four cutting edges to extend the service life of the blade.

5. Adjust the cutting stroke, which can not only improve the processing efficiency, but also realize the segmented cutting function.

6. The light alignment function makes the alignment cutting more convenient.

| Adjustment of shear angle When the machine cuts different specifications of sheet material, by adjusting the size of the shear angle, The amount of deformation of the material to be cut is reduced to the ideal state. |

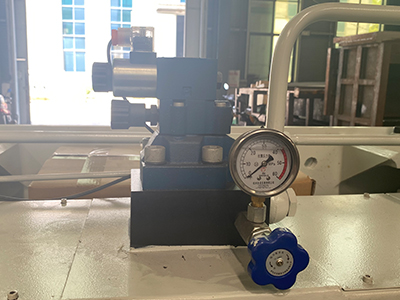

Blade clearance adjustment The proper blade clearance will give you satisfactory cutting results. The machine is equipped with a quick blade clearance adjustment mechanism. |

|

| Three-point roller guide tool frame structure Adopt three-point roller guide tool holder structure, the front prepress guide rail to make the tool holder Always stick to the upper guide rail and the lower guide rail for no gap reciprocating action, when cutting different plates, the blade clearance can be adjusted, so that the cutting quality is better. |

Three-point roller guide tool frame structure the front prepressed guide rail makes the tool rest always stick to the upper guide rail and When cutting different plates, the blade gap can be adjusted to make the cutting quality better. |

|

| 1. The use of advanced integrated hydraulic system, reduce pipeline installation, control oil leakage to a minimum, It ensures high reliability and safety in the operation of the machine. 2. The hydraulic press mechanism is adopted, and the press force changes with the load, making the shear more reliable. |

Numerical control system which provides programming control for the shearing machine. |

|

| Backgauge The effective stroke of the rear stop is 1000mm, driven by the servo motor, to achieve the purpose of parallel positioning. |

Electrical control system all electrical components are made of Siemens. all wires are printed with PVC pipe line number. |

|