Swingbeam ShearsShearing Machine

1) To provide customers with better cost-effective solutions.

2) Complete welded frame structure, machine rigidity is good.

3) The frame adopts a large CNC boring and milling machine for overall processing to ensure cutting accuracy and quality.

4) The cutting edge gap adjustment is quick, convenient and accurate.

5) The shear stroke can be adjusted stepless to improve the shear efficiency.

6) Nitrogen cylinder return, stable and reliable work.

7) Special CNC system for shearing machine, with high precision and easy operation.

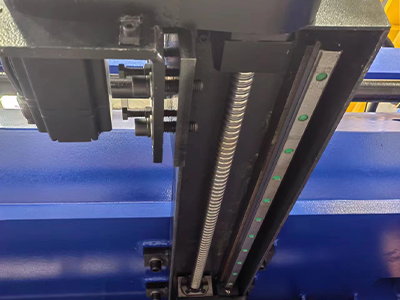

8) Backgauge adopts ball screw, linear guide rail structure, servo motor drive, accurate and reliable positioning.

9) Spherical ball bearing table, easy for users to feed.

10) The front supporting rod is equipped with a front positioning scale, and the mechanical stop block is positioned.

11) With light lighting, easy to cut.

12) Optional pneumatic rear support material.

| ● The lower end of the press cylinder is equipped with a special material gasket to avoid leaving marks on aluminum alloy or other sensitive materials ● Pressure of hold down cylinders changes with the thickness of the cut sheet material. *High quality alloy tool steel material 6CrW2SI (standard shear blades) is used to cut ordinary carbon steel ● Optional material is Cr12MoV shear blades, for cut stainless steel plate● The upper blade is a parallelogram, and the lower blade is a rectangular segment blade |

|

| Backgauge ● The backgauge is installed on the upper tool holder and moves up and down with the upper tool holder. ● Backgauge plate is driven by the servo motor arc tooth synchronous belt, linear guide rail guide screw drive. |

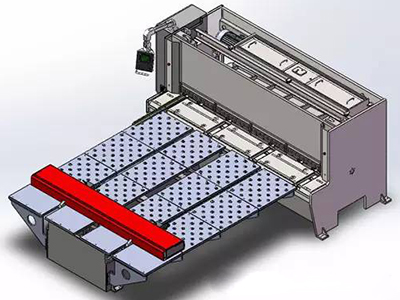

| Front table section The work table is equipped with a universal rolling ball, which can reduce friction resistance and reduce scratches on the workpiece surface. The front guardrail meets the safety standards to protect the personal safety of the operator. The left pallet is equipped with a sliding stop, ruler and side positioning baffle to meet the needs of customers in front positioning shear plate. |

|

| Blade clearance adjustment The clearance adjustment by operates the handle rotation manually, and m fine-tune the clearance between the upper blade and the lower blade on the tool rest to meet the clearance value required when cutting plates of different thicknesses |

| Integrated hydraulic system Hydraulic valve system for domestic pendulum shear |

|

| CNC front feeding device (Optional) The CNC front feed is installed in front of the shearing machine, and the feeding table is equipped with a conveying ball, which reduces the feeding resistance and avoids the surface scratch of the workpiece; |

| The sheet material is placed on the feeding table, and the sheet material is held by the pneumatic clamp, and automatically fed and positioned according to the programmed setting value, and coordinated with the movement of the knife holder of the shearing machine, single and continuous automatic cutting is carried out, which greatly improves the cutting accuracy and reduces the labor intensity. Pneumatic long clamp, high working efficiency, small working dead zone; |

|