CNC PressbrakeBending Machine

WF67K series electro-hydraulic synchronous CNC Pressbrake (hydraulic compensation). The introduction of European design concept, simple appearance, practical and efficient, stable and reliable, cost-effective, with high process accuracy and strict safety standards, low failure rate of the new generation of CNC bending machine.

(1) The main mechanical structure of the machine tool is composed of the frame, the column, the slide block, the workbench, the main cylinder and the rear material. The main components are analyzed and optimized by three-dimensional software to ensure the structural strength and rigidity of each component.

(2) Welding parts using tempering, vibration aging and other methods to eliminate the internal stress of components;

(3) The guide rail of the machine tool adopts advanced self-lubricating materials, without frequent lubrication maintenance;

(4) The transmission structure of the machine tool adopts the up-moving bending design to ensure low noise and smooth working state; The bottom dead center has the function of suspending the pressure to ensure the accuracy of the workpiece;

(5) The movement and positioning of the left and right cylinders are controlled by the Y1 and Y2 axes, and the full closed-loop control system is composed of the electro-hydraulic servo valve grating numerical control system. Each axis can work in the programming state to make the slider of the machine tool have a higher motion positioning accuracy when pressing the workpiece. The linear scale is connected with the table to eliminate the influence of the column deformation on the position of the slider.

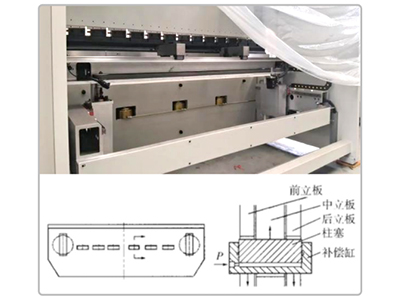

(6) The deflection compensation of the workbench is controlled by the V-axis of the CNC system. The automatic hydraulic deflection compensation mechanism consists of a set of deflection compensation cylinders, which are set below the workbench. When working, the CNC system controls the relative displacement of the compensation cylinder according to the size of the load to form a cluster of ideal compensation curves. The sliding block is provided with a diagonal wedge compensation mechanism to compensate the wear caused by excessive working time of the upper and lower die;

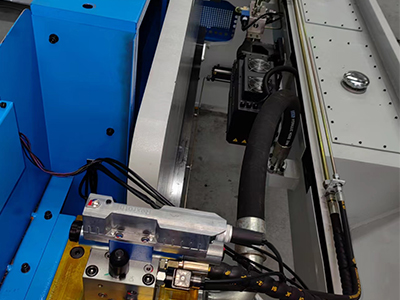

(7) Backgauge is controlled by the X-axis servo motor of the CNC system to drive the ball screw and the linear guide;

(8) The numerical control system is placed on the hanging operation station, and the operation can be freely swung in the operation area, single operation, etc. It is equipped with movable foot switch to move freely in the work area.

| Machine tool structure 1. Latest technology design, the whole steel plate welding structure, high strength, high stiffness; |

Hydraulic Compensation Table When bending sheet material, the block and the table support plate will inevitably produce flexural deformation, so that the bending angle of the workpiece is small at both ends and large in the middle. The machine is equipped with compensation cylinder and controlled by CNC system, which makes the lower table produce pre-convex compensation for the deflection of the upper slider, and controls the angle change of the workpiece within the tolerance range to ensure high quality bending accuracy. Hydraulic compensation has less maintenance and no wear problems than mechanical compensation. Before hydraulic compensation, the lower table is the overall plane state and the surface of the bent plate contact state, and it is very stable when the upper die and the plate contact "clamping point", that is, the plate can not be displaced. |  |

| Backgauge |

Hydraulic system |  |

| Slide front support |

European-style fast clamp |

|

| Main motor |

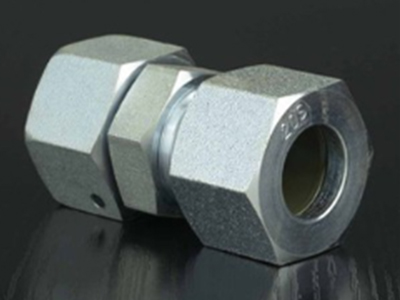

Bushing joint |

|

| Servo motor |

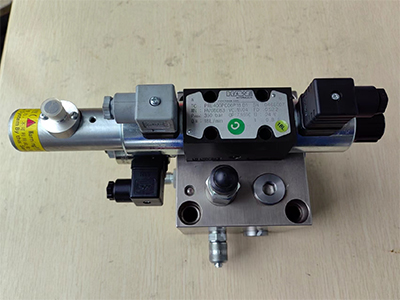

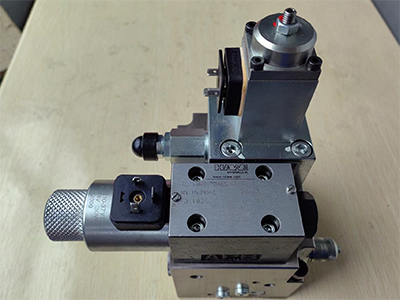

Proportional valve |

|

| Hydraulic valve |

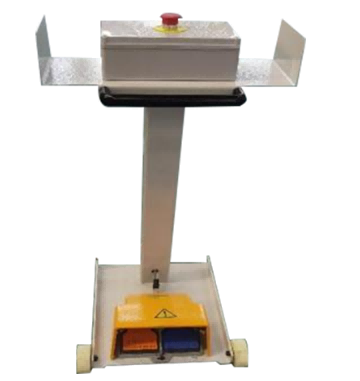

KACON foot switch |

|